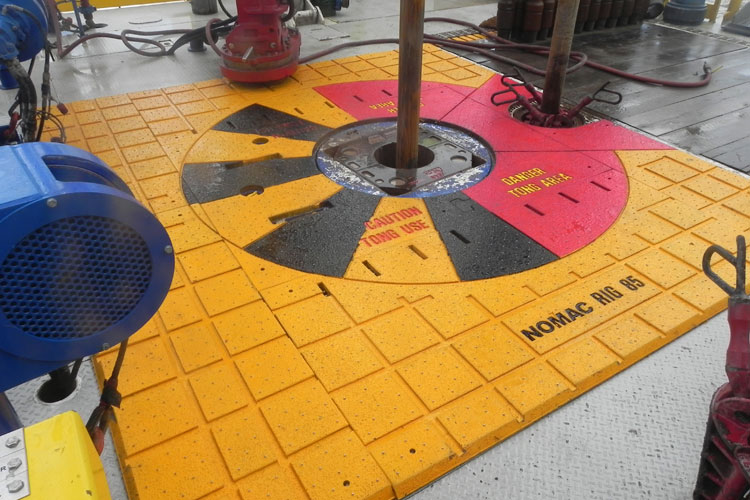

Safety Pad II FR

Since 1979, over 8,000 rigs worldwide have used the Safety Pad II FR with outstanding results. It is molded from a high strength 100% solid urethane elastomer and offers extreme hydrolytic stability, anti-fungal properties, ultraviolet stability, fire retardant properties, and chemical or diesel resistance. This high-traction safety mat can be custom molded in various thicknesses to fit rotary tables, drill rig floors and any other critical work or walk area.

Safety Pad II FR is known to outlast our leading competitors mat by 2-3 times and has been tested and approved by the Norwegian Maritime Directorate. This approval is based on test certificate 250010.40/92.238 dates 7/31/92, Sintef NBL - Norwegian Fire Research Laboratory. The test method is Solas (Safety of Life At Sea) NT Fire 007-NS-Insta 414).

Drainage grooves are molded into the surface of the mats to assist in the control of fluids that can accumulate. All pads come standard with a non-skid coating for additional traction and durability. This coating also creates a barrier of protection from chemicals, diesel, other corrosive fluids and ultra-violet rays.

"If you're not using Safety Pad II FR, you're slipping!"

Rotary Table

Our standard thickness for Safety Pad II FR rotary table mats is 1 1/4". Thicker options are available for recessed rotaries or other situations where the drill floor is not level. Safety Pad II FR comes standard with stainless steel studs protruding from its non-skid surface along with drain grooves to help disperse drilling fluids.

Movable Pipe Rack

If you're racking pipe on wood, a Movable Pipe rack is available. Cleats on the bottom of the pad bite into the wood to prevent movement. As the rack fills with drill pipe, two men can relocate the pad as needed.

Derrick Area & Steps

This high-traction work surface is custom molded 3/4" thick for use on stairways, derrick boards, and workover rigs.